Resolution test targets for high-end microscope lenses

Smallest structural sizes thanks to e-beam lithography

- Structural sizes down to 100 nm

- Optimal contrast due to high optical density

- Robust design for everyday use

Resolution test targets from Technologie Manufaktur – produced with the best technology worldwide

All of our resolution test targets are made with high-precision e-beam lithography. The 10 x 10 mm² substrate consists of quartz, offering very broad spectral transmission (DUV-VIS-NIR). A chromium layer with high optical density is applied to the substrate.

The test structures are produced by ablation of the chromium layer, whereby structural sizes down to 100 nm are possible as a result of the e-beam process. At the same time, excellent dimensional tolerances and straightness of the structural edges are ensured. Through ablation of the chromium layer, the structures of the test slide are transparent, while the background is blocked by the remaining chromium layer.

The resolution test targets are embedded in a robust stainless steel support with a standard size of 75×25 mm². For use with a microscope objective a version in available with a 0.17 mm cover glass.

Down to 100 nm

OD6 @550 nm

190 nm – 2000 nm

from Technologie Manufaktur

Product specifications

|

Request for your individual test chart

Contact us now

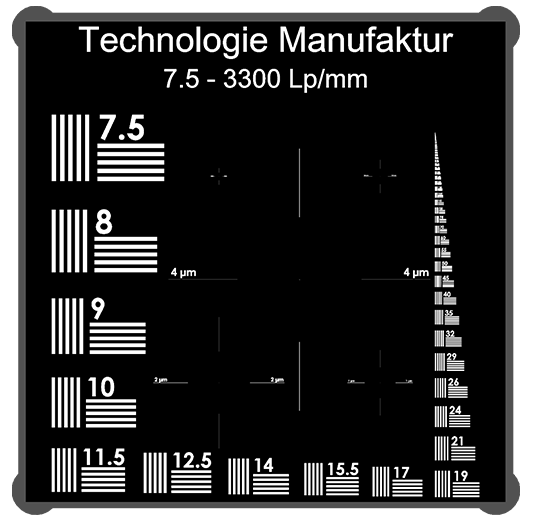

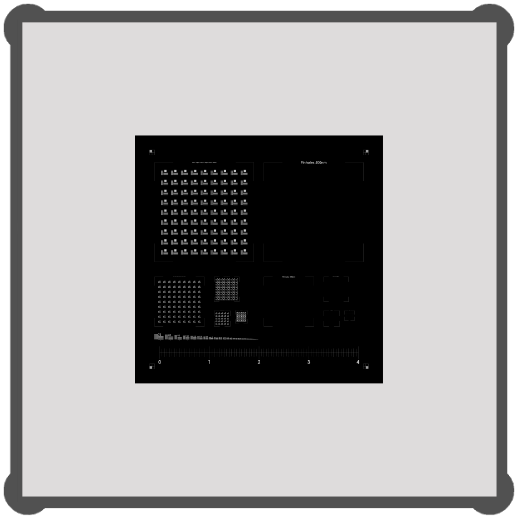

Resolution test target TC-RT01

With the TC-RT01 resolution test target, the resolution limit of a lens can be determined very easily and quickly in transmitted light. The simple arrangement of the line pattern groups along with size readings ensures intuitive handling. In addition, 5 pinholes allow characterization of any optical imaging errors.

•For resolution test target with transmitted light

• 59 line pattern groups: 7.5 – 3300 LP/mm

• 3300 LP/mm requires an immersion lens or UV light

• 5 pinholes (Ø 4.0 µm – 0.25 µm)

Price: 1050 Euros plus sales tax

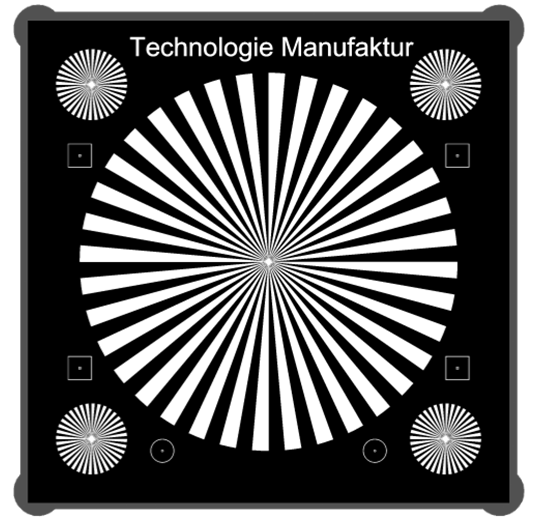

Siemens Star TC-RT02

The Siemens Star TC-RT02 resolution test target is especially suitable for microscope lenses of very high numerical aperture. Precision manufacturing of the segments in the centre of the 5 Siemens Stars allows a minimum width of 150 nm. Additional measuring and positioning marks facilitate exact adjustment.

- For microscope lenses with a very high numerical aperture (NA)

- 5 Siemens Stars

- Minimum width in centre: 150 nm

- Additional measuring and positioning marks

Price: 1050 Euros, plus sales tax

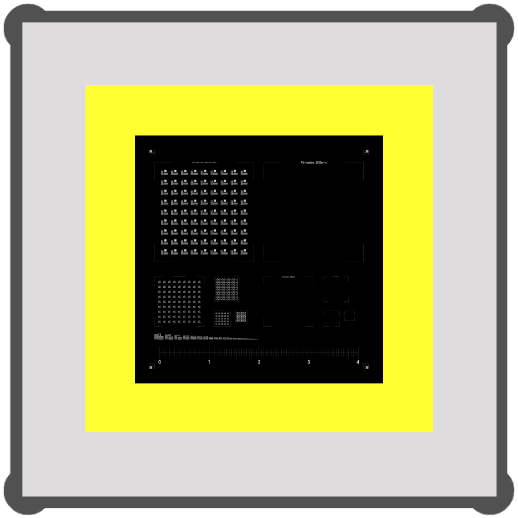

Fluorescent resolution test target TC-RT03fl

With this fluorescent ultra-high-resolution test chart the resolution limit and MFT of high-end microscope objective lenses can be determined over the full field of view. Line patterns with a pitch down to 200nm (5000 line pairs per mm) in horizontal and vertical alignment make it possible to access the resolution limit of the best available oil immersion objectives.

- With cover glass for transmitted light and wide-field fluorescence microscopy

- Also for laser scanning microscopes

- No bleaching (YAG:Ce crystal)

- Line groups from 75 – 5000 lines/mm (200nm pitch)

- Fields with 20×20 pinholes for objectives from 10x to 100x

- Fields with squares for slanted-edge MTF

Price: 1700 Euros, plus sales tax

TC-RT03mat resolution test target for material microscopy

This test chart is designed like the TC-RT03fl, but does not have a cover glass and can therefore be used for high-end material microscopy objectives.

- Without cover glass for wide field and laser scanning microscopes

- Line groups from 75 – 5000 lines/mm (200nm pitch)

- Fields with 20×20 pinholes for objectives from 10x to 100x

- Fields with squares for slanted-edge MTF

Price: 1500 Euros, plus sales tax

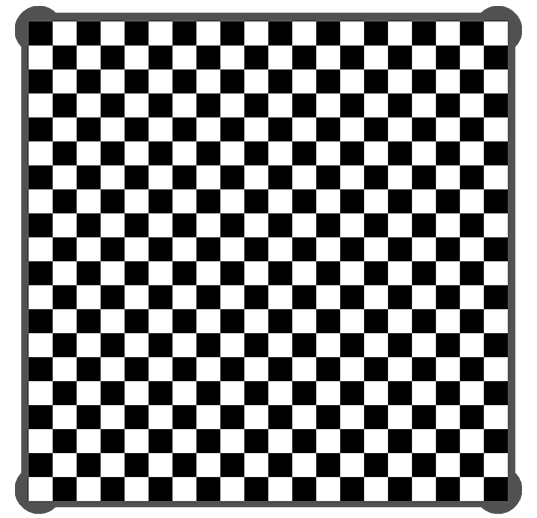

Checkerboard TC-CB50

Our TC-CB50 test target offers a checkerboard with 180×180 fields, each with a size of 50 x 50 µm², and is therefore especially suitable for testing image skew and image field curvature. Furthermore, the very sharp edges of the field allow you, for example, to determine the local image quality of a camera. With our Slanted-Edge software package you can determine modulation transfer functions (MTF).

• Testing image skew and image field curvature

• Determine local image quality

• Determine the MTF with our in-house software package

• Total size 9.0 x 9.0 mm²

• Fields: 50 x 50 µm² each

Price: 950 Euros, plus sales tax

High-Tech from Technologie Manufaktur: Precision through e-beam lithography

In order to be able to test the resolution of high-end microscopes, resolution test targets must be able to show the smallest and most precise structures. This is not possible using conventional photo-lithographic means.

For this reason, in the manufacture of our resolution test targets we use state-of-the-art e-beam lithography. E-beam lithography is primarily used in the semiconductor industry. The individual structures are written onto the wafer with an electron beam.

Although this next-generation lithography takes longer and is more expensive, it allows incomparable precision in terms of structures.

Manufacturing with electron beam lithography must take place in a clean room, since even a few particles can disrupt the structuring of the chromium layer.